The Process of Installing a Single Split Air Conditioning System

Installing a single split air conditioning system involves several stages, from initial planning to final commissioning. For facilities, operations, and compliance professionals, understanding this process ensures not only effective cooling but also a safe, compliant, and efficient installation.

1. Preparation and Planning

A surveyor first identifies the capacity of the system required. This is calculated using the room dimensions, the room’s purpose, occupancy levels, and the size and orientation of windows and doors. These factors help determine the correct system size to maintain comfort and energy efficiency.

The surveyor also assesses the most suitable locations for the internal and external units, discussing options with the customer before installation begins. At this stage, safety and compliance considerations are key, ensuring electrical access points, ventilation, and drainage all meet current standards and that installation methods comply with F-Gas and building regulations.

2. Indoor Unit Installation

Once the capacity and unit types are confirmed, the installation area is prepared.

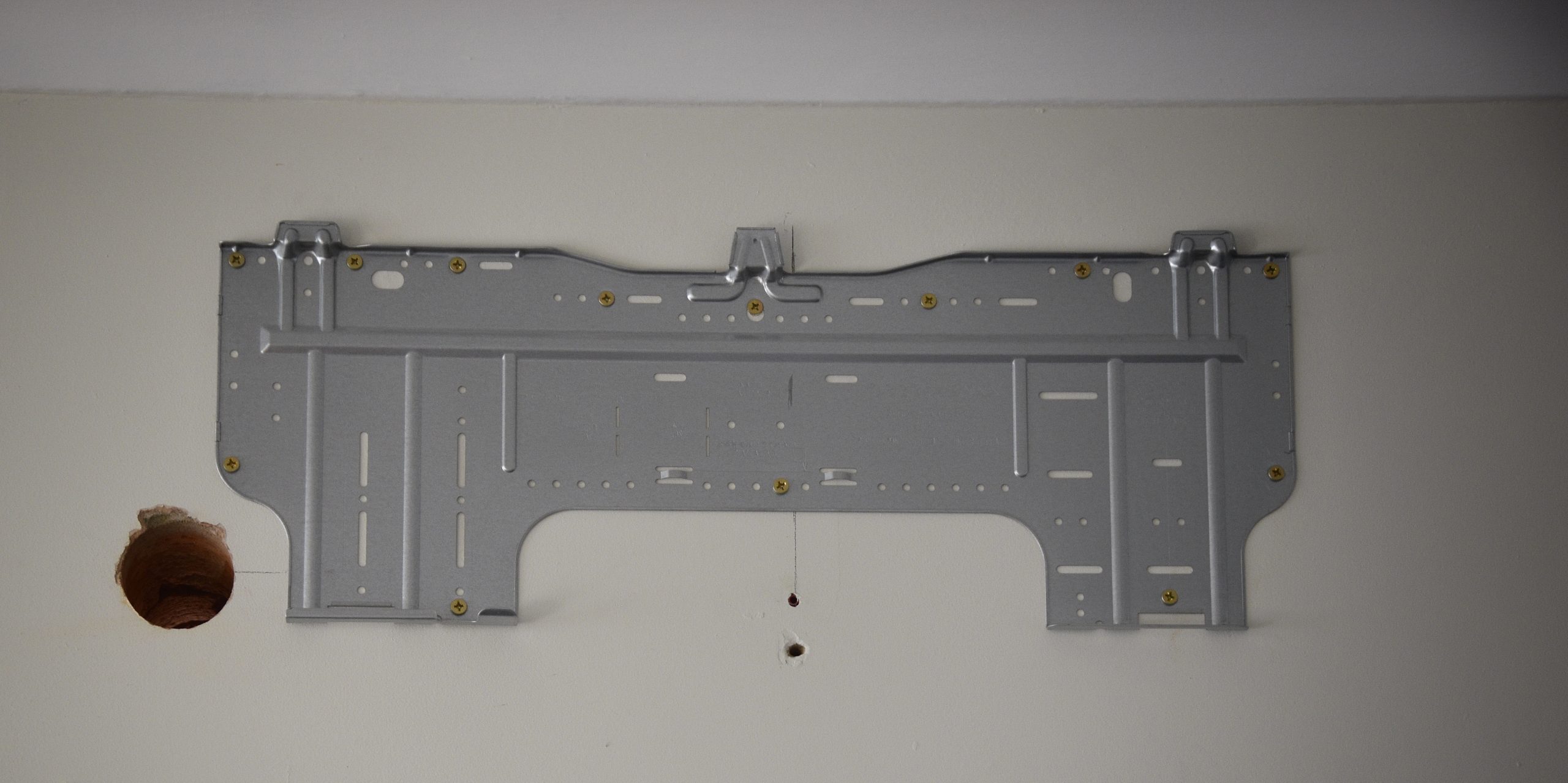

Mounting Plate Installation

The mounting plate must be perfectly level, fixed securely with suitable anchors, and the wall must be able to support the unit’s weight and vibration.

Drilling the Core Hole

A 65–75 mm hole is drilled through the wall to route the refrigerant pipes, condensate drain, and cables. The hole is angled slightly downward to allow condensation to drain naturally. Dust extraction or containment should be used where possible to maintain safe working conditions and minimise disruption.

3. Outdoor Unit Installation

Site Selection

A well-ventilated location is chosen, away from obstructions, dust, or quiet areas like offices or bedrooms. The unit’s position should balance performance with visual and noise considerations.

Mounting the External Unit

If placed on the ground, the base must be level, often using concrete slabs and rubber blocks to absorb vibration. If wall-mounted, anchor bolts and rubber pads ensure security and noise reduction. Any external pipework is secured neatly along the wall.

At this stage, compliance with environmental and planning requirements (such as noise limits and proper drainage) is verified.

4. Connecting the Systems

Refrigerant pipes are routed between the indoor and outdoor units, cut to length, flared, and fully insulated. The drain hose is connected to the indoor outlet with a consistent downward slope, and the pipes, hose, and electrical cables are wrapped together neatly.

Electrical connections follow the manufacturer’s wiring diagram, with polarity and terminals checked twice for safety. The condensate drains are routed to suitable outlets to prevent water damage or contamination risks.

5. Vacuum and Leak Testing

Vacuuming the System

Using a manifold gauge set and vacuum pump, the system is evacuated for 15–30 minutes until it reaches below 500 microns. This confirms the removal of moisture and air, ensuring reliable operation.

Leak Test

Leaks are checked with soapy water or an electronic detector. Proper testing is critical for F-Gas compliance, as refrigerant leaks can harm efficiency and the environment.

6. Commissioning and Testing

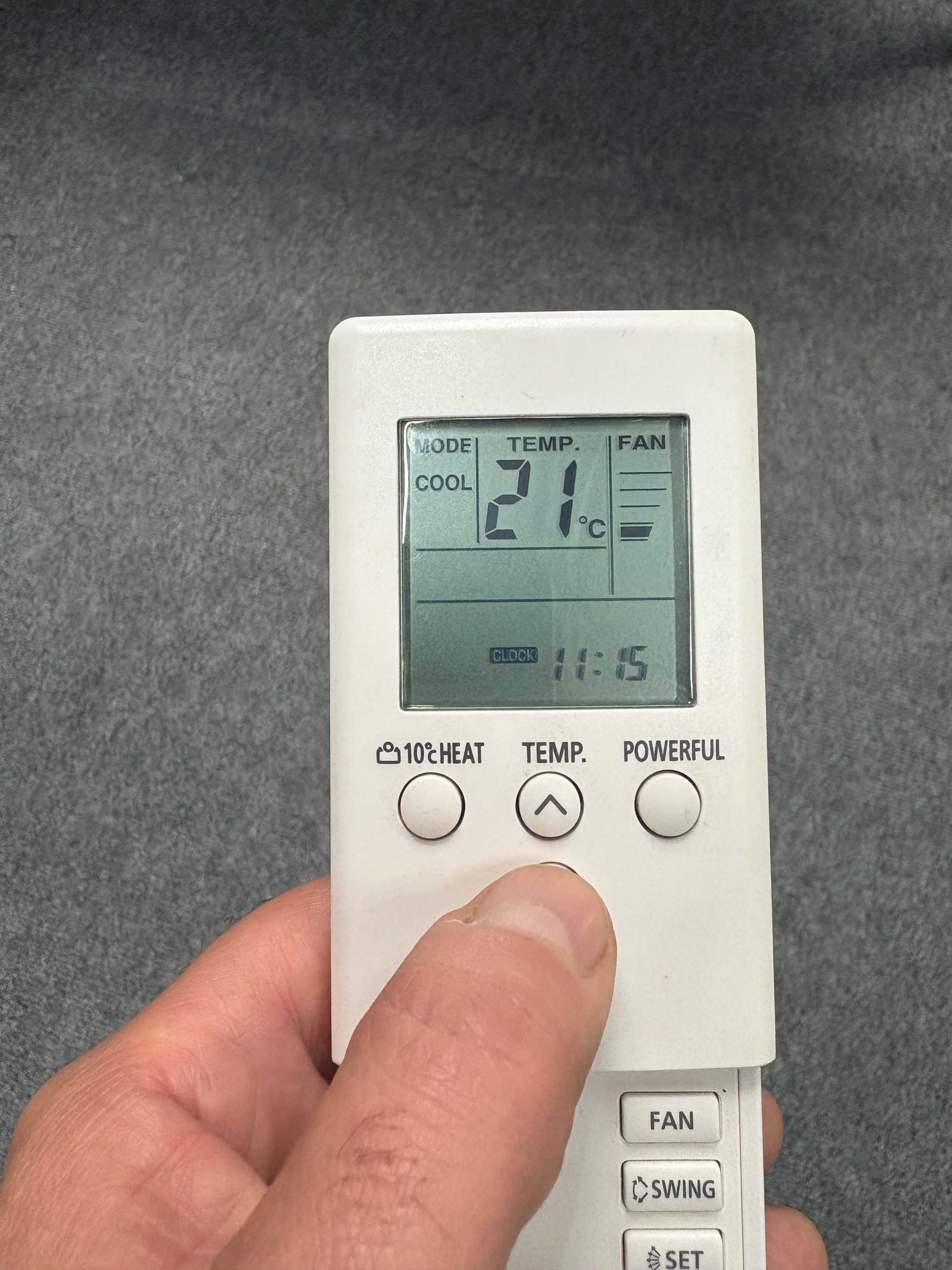

Once testing is complete, the service valves are opened and the system is powered on. It is then run in both cooling and heating modes to verify performance against manufacturer specifications.

Engineers check air-off temperatures, noise, vibration, and condensation drainage to confirm safe and efficient operation. Detailed commissioning records are kept for traceability, an essential part of operational compliance.

7. Final Steps

Finally, wall penetrations are sealed with silicone or foam, and all internal and external areas are cleaned down. Installation details, serial numbers, refrigerant type, pressures, and temperatures, are recorded, and a full operational demonstration is provided to the customer, including use of the controller or app.

Supporting Safe and Compliant Installations

At every stage, from planning to handover, [Client Name] applies a safety-led, compliant approach to ensure all installations meet regulatory standards and manufacturer specifications. Our engineers are trained in F-Gas and electrical safety, helping clients maintain both comfort and compliance across their operations.

Conclusion

Installing a single split air conditioning system is a detailed process requiring precision, safety awareness, and regulatory knowledge. When carried out correctly, it ensures long-term efficiency and performance.

Find out how we can support your next installation with expert, compliant air conditioning solutions.